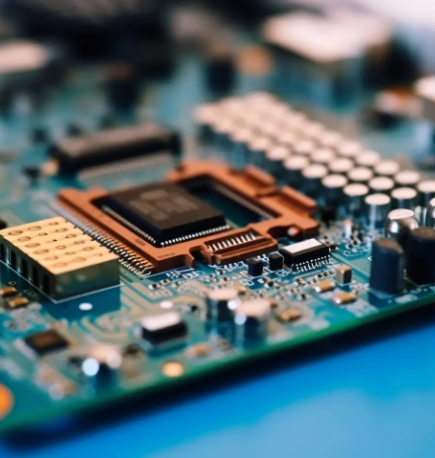

PCBA ṭha famkim design-naah hian ngaihtuah tur tam tak a awm

PCBA (Printed Circuit Board Assembly) ṭha famkim design tur chuan thil tam tak ngaihtuah a ngai a, circuit design atanga component thlan thlengin, production leh testing thlengin. A hnuaia tarlan te hi harsatna thenkhat, PCBA design-a thil pawimawh tak tak leh design tha famkim neih theihna tura hmanraw hrang hrangte tarlan a ni.

1. PCBA design lama harsatna awm thei

Circuit Complexity: Tunlai electronics te hi a chak chho zel a, chu chuan circuit design buaithlak tak tak a siam ta a ni. Multilayer board, high-speed signal, mixed signal (analog leh digital), etc. te hian design harsatna a tizual vek dawn a ni.

Thermal management: High-power components hian lumna nasa tak a siam ang.

Electromagnetic compatibility (EMC): Electronic hmanrua te hian electromagnetic compatibility standard hrang hrang a tlin a ngai a, design-ah hian electromagnetic interference (EMI) leh electromagnetic susceptibility (EMS) te control a ngai bawk.

Space limitation: A bik takin miniaturized electronic product-ah chuan PCB area a tlem a, space tlemte chhunga component leh trace te dah dan tur chu a harsa hle.

Thil siam dan: Thil siam dan hrang hrang hian design atan mamawh hrang hrang an nei a, chu chu surface mount technology (SMT) leh through-hole technology (THT) te inzawmkhawm a ni.

Cost control: Performance leh quality enfiahna kawngah chuan cost control dan pawh hi design lama harsatna lian tak a ni.

2. PCBA design chungchanga thil pawimawh tak tak

Design mamawh chiang tak: Design i siam hmain product-a functional requirements, performance indicators, environmental requirements, etc. te chiang taka sawi hmasa phawt ang che. Design-te beisei ang a nih theih nan customer mamawh leh industry standard hriatthiam.

Circuit design dik tak: Circuit topology dik tak thlang la, power leh ground wire te chu a remchan dan angin sem la, signal integrity enfiah rawh. Complex circuit tan chuan simulation software hmangin verification hman theih a ni.

Component thlan: Component rintlak leh stable performance nei thlang la, an supply chain dinhmun ngaihtuah rawh. Component power hman dan leh thermal management te ngaihven rawh.

PCB layout leh routing: 1.1.

Layout: Components te chu a remchan dan anga remkhawm la, signal path, power distribution leh heat dissipation path te ngaihtuah chungin. Key component leh sensitive circuit te hi dah pawimawh hmasak tur a ni.

Wiring: High-speed signal, analog signal leh digital signal te chu a remchan dan anga sem chhuah theih nan circuit function angin partition a ni. Trace sei zawng leh zau zawng ngaihven la, via tam lutuk loh tur.

Power management: Module tin hian power dik tak an dawn theih nan power system nghet tak design rawh. Filter capacitor leh power distribution network (PDN) hmangin power quality tha zawk siam.

Heat dissipation design: Heating components atan hian heat dissipation solution dik tak design tur a ni a, chu chu heat dissipation copper foil dah belh te, heat sink emaw fan emaw hman te, etc. te hi a ni. PCB chhung zawngah heat distribution inang tlang taka awm theih nan hma la rawh.

3. PCBA ṭha famkim design dan

Inbuatsaihna hmasa ber:

Project mamawh chipchiar taka hriatthiam a, design specification kimchang ziak.

Design siam theih leh test theihna tur department kaihhnawih (e.g. mechanical design, software development, manufacturing engineering) te nena inbiakpawhna neih.

Project te a hun taka tihfel a nih theih nan design plan leh timeline siam.

Circuit design leh simulation te chu:

Circuit design atan professional EDA software hmang la, design chu specification zawm a nih leh nih loh enfiah rawh.

Key circuit-ah simulation verification neih a, harsatna awm thei te chu a hmain hmuhchhuah leh chinfel a ni.

PCB layout leh routing: 1.1.

EDA software-ah PCB layout leh routing tih a ni a, signal integrity leh power integrity ngaihven rawh.

PCB design tihchangtlun nan automatic routing leh manual adjustment hmanga siam a ni.

Design thlirletna leh tihchangtlun dan:

Design review neih a, design dik leh rationality enfiah turin mithiam tam tak tel turin sawm.

Review comments atanga optimize la, signal integrity, power integrity, leh thermal design te chu a bik takin ngaihven rawh.

Prototype siam leh test dan:

Prototype siam te, functional test te, performance test te leh environmental test te neih a, design rintlak leh nghet lo tih finfiah.

Test neih chhunga harsatna hmuhchhuah te chu zirchiang la, siam\hat la, a tul chuan design thar leh rawh.

Mass production atana inbuatsaihna:

Prototype test a pass tawh tih i finfiah hnuah mass production atan inbuatsaih rawh. Mass production laiin harsatna a awm loh nan thil siamtute nen inbiakpawhna neih thin ang che.

PCBA tinte chu uluk taka test a nih theih nan leh quality mamawh a tlin theih nan testing plan kimchang siam.

keep improve: tihchangtlun zel rawh:

Mass production hnua feedback information khawlkhawm a, harsatna awm fo te thlirlet a, hmasawnna chhunzawm zel.

Production efficiency leh quality control tha zawk neih theih nan design leh manufacturing process te endik fo thin.

Heng step leh key points te hi khauh taka zawm hian PCBA design lama harsatna awmte chu tha takin i hmachhawn thei a, PCBA quality sang, performance tha zawk design i ti thei a, customer leh market mamawh i phuhruk thei bawk.