Isishwankathelo soyilo lwePCB amanqaku aphambili: izinto ezininzi ekufuneka uziqwalasele

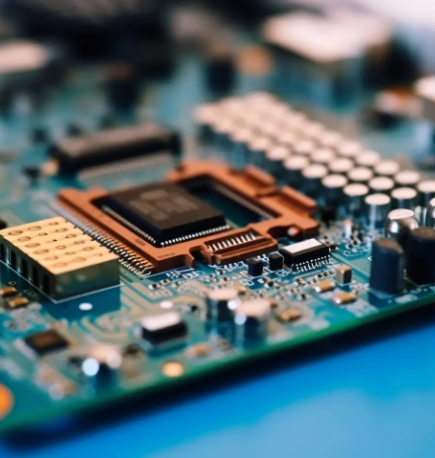

Ibhodi yesekethe eprintiweyo (PCB) uyilo likhonkco elibalulekileyo kuphuhliso lwemveliso yombane. Uyilo lwePCB olulungileyo alunakuphucula kuphela ukusebenza kunye nokuthembeka kwesekethe, kodwa nokunciphisa iindleko zemveliso kunye nobunzima bokulondoloza. Oku kulandelayo ngamanqaku amaninzi kunye nemiba efuna ukuhoywa kuyilo lwePCB.

1. Uyilo lomzobo wesekethe yesikimu

Ngaphambi kokuba uqhubeke noyilo lwePCB, kufuneka uqale ugqibezele uyilo lomzobo wesekethe yesikimu. Eli nyathelo alikho kuphela isiseko soyilo lwePCB, kodwa kunye nemfuneko yokuqinisekisa umsebenzi wesiphaluka kunye nokusebenza. Xa uyila umzobo weskimu sesekethe, kufuneka ubeke ingqalelo kula manqaku alandelayo:

Cacisa imisebenzi kunye neemfuno: Ziqonde ngokucacileyo iimfuno zokusebenza kunye nokusebenza kwesekethe kwaye uqinisekise ukuba uyilo luyakwazi ukuhlangabezana nezi mfuno.

Khetha amacandelo afanelekileyo: Khetha amacandelo afanelekileyo ngokusekwe kwimisebenzi yesekethe, uthathele ingqalelo izinto ezifana nokusebenza kwecandelo, ukupakishwa, kunye neendleko.

Phawula iilogo ezicacileyo kunye neeparamitha: Qinisekisa ukuba iilogo zecandelo kunye neeparameters kwidayagram yeskim zicacile kwaye zichanekile ukuququzelela uyilo lwePCB olulandelayo kunye nokulungiswa kweempazamo.

2. Uyilo olufanelekileyo

Uyilo lwecandelo olufanelekileyo yinxalenye ebalulekileyo yokuqinisekisa ukusebenza kwePCB. Uyilo kufuneka luqwalasele ngokubanzi imiba emininzi efana nomsebenzi wesekethe, imfezeko yomqondiso, ulawulo lwe-thermal, njl. Nantsi eminye imiba yoyilo:

Ukwahlula okusebenzayo: Ukwahlula isiphaluka kwiimodyuli ezisebenzayo kwaye ubeke amacandelo eemodyuli ezifanayo ezisebenzayo kunye kunye nokunciphisa iindlela zokuhambisa umqondiso.

Ingqibelelo yoMqondiso: Imigca yomqondiso wesantya esiphezulu kufuneka ibemfutshane kwaye ithe ngqo kangangoko kunokwenzeka ukuphepha ukuphazamiseka okunqamlezayo. Imigca yemiqondiso engundoqo efana nemigca yewotshi, imigca yokuseta ngokutsha, njl.njl. kufuneka igcinwe kude kwimithombo yengxolo.

Ulawulo lwe-Thermal: Amacandelo anamandla aphezulu kufuneka asasazwe ngokulinganayo, kwaye imiba yokutshatyalaliswa kobushushu kufuneka ithathelwe ingqalelo, ukuba i-radiator okanye imingxuma yokushisa kufuneka yongezwe.

3. Imigaqo yomzila

Umzila lelinye ikhonkco eliphambili kuyilo lwePCB olunengqiqo lunokuthintela ukuphazamiseka komqondiso kunye nokulibaziseka kothumelo. Oku kulandelayo ngamanqaku athile ekufuneka uwaqaphele xa usendleleni:

Ububanzi bomgca kunye nesithuba: Khetha ububanzi bomgca obufanelekileyo ngokobukhulu bangoku ukuqinisekisa ukuba umgca unokumelana nombane ohambelanayo. Gcina isithuba esaneleyo phakathi kwemigca yemiqondiso eyahlukeneyo ukuphepha ukuphazamiseka komqondiso.

Inani lee-wiring layers: Iisekethe eziyinkimbinkimbi ngokuqhelekileyo zifuna i-wiring ye-multi-layer cwangcisa ngokufanelekileyo i-wiring yoluhlu ngalunye ukuze kuqinisekiswe ukuhanjiswa okulungileyo kwemigca yesignali kunye neentambo zamandla.

Gwema ukujika okubukhali: Gwema ukujika okubukhali xa uhamba, kwaye uzame ukusebenzisa i-45-degree oblique ejikayo ukunciphisa ukubonakalisa umqondiso kunye nokuphazamiseka.

4. Unikezelo lwamandla kunye noyilo lomhlaba

Unikezelo lwamandla kunye noyilo lwesiseko zizinto eziphambili eziphambili zoyilo lwePCB, ezichaphazela ngokuthe ngqo ukuzinza kunye nokukwazi ukuchasana nokuphazamiseka kwesekethe. Oku kulandelayo kukuqwalaselwa kwamandla kunye noyilo lomhlaba:

Umaleko wamandla kunye nomgangatho womhlaba: Sebenzisa umaleko wamandla ozimeleyo kunye nomgangatho womhlaba ukunciphisa i-impedance phakathi kokunikezelwa kwamandla kunye nomhlaba kunye nokuphucula umgangatho wamandla.

I-Decoupling capacitor: Lungiselela i-decoupling capacitor kufuphi ne-pin yamandla ukucoca ingxolo ephezulu-frequency kunye nokuqinisekisa ukuzinza kokunikezelwa kwamandla.

Umjikelo osezantsi: kunqanda uyilo lwe-loop yomhlaba kunye nokunciphisa ukuphazamiseka kwe-electromagnetic. Iingcingo eziphantsi kwemigca yeempawu ezibalulekileyo kufuneka zibe mfutshane kwaye zithe ngqo ngokusemandleni.

5. Uyilo lwe-EMI / EMC

Ukuphazamiseka kombane (i-EMI) kunye noyilo lwe-electromagnetic comppatibility (EMC) ngundoqo ekuqinisekiseni ukuba ii-PCBs zisebenza ngokufanelekileyo kwiindawo ezintsonkothileyo zombane wombane. Oku kulandelayo yi-EMI/EMC yokuqwalaselwa koyilo:

Uyilo lokukhusela: Khusela imiqondiso ebuthathaka kunye nezinto ezinengxolo ephezulu ukunciphisa ukuphazamiseka kombane.

Uyilo lwesihluzi: Yongeza izihluzi kubonelelo lwamandla kunye nemigca yesiginali ukucoca imiqondiso yengxolo kunye nokuphucula ukuhambelana kombane.

Uyilo lomgangatho: Uyilo oluhle lokumisa lunokucinezela ngokufanelekileyo ukuphazamiseka kwe-electromagnetic kunye nokuphucula amandla okuthintela ukuphazamiseka kwesekethe.

6. IMiqathango yokuVelisa kunye neNdibano

Uyilo lwePCB akufunekanga luqwalasele ukusebenza kwesekethe kuphela, kodwa nokuba nokwenzeka kokuvelisa kunye nokuhlanganisana. Nanga amanye amanqaku ekufuneka uwaqaphele xa kusenziwa kwaye kudityaniswa:

Ukupakishwa kwecandelo kunye nezithuba: Khetha amacandelo apakishiweyo asemgangathweni ukuqinisekisa isithuba esaneleyo sendibano ukuququzelela ukuwelda kunye nokugcinwa.

Uyilo lwamanqaku ovavanyo: Lungiselela amanqaku ovavanyo kwiindawo eziphambili zokuququzelela uvavanyo lwesekethe olulandelayo kunye nokulungisa iingxaki.

Inkqubo yokuvelisa: Qonda kwaye ulandele imigaqo yenkqubo yabavelisi bePCB ukuqinisekisa ukuba uyilo luyahlangabezana neemfuno zokuvelisa.

ukuququmbela

Uyilo lwePCB yinkqubo entsonkothileyo necekethekileyo, ebandakanya imiba emininzi efana noyilo lwesikimu sesekethe, uyilo lwecandelo, imithetho yendlela, unikezelo lwamandla kunye noyilo lokubeka umhlaba, uyilo lwe-EMI/EMC, ukwenziwa kunye nokuhlanganisa. Yonke inkalo ifuna ukuqwalaselwa ngenyameko ngabaqulunqi ukwenzela ukuyila ibhodi yesekethe kunye nokusebenza okugqwesileyo, ukuzinza kunye nokuthembeka. Ngesishwankathelo seli nqaku, ndiyathemba ukubonelela ngesalathiso kunye nesikhokelo kubayili bePCB ukuphucula umgangatho kunye nokusebenza kakuhle koyilo lwePCB.

- 2024-06-21 08:42:23

- Next: Kukho imiba emininzi ekufuneka uyiqwalasele xa uyila iPCBA egqibeleleyo