PCB nhyehyɛɛ ho nsɛm tiawa: nneɛma pii a ɛsɛ sɛ wohwɛ so yiye

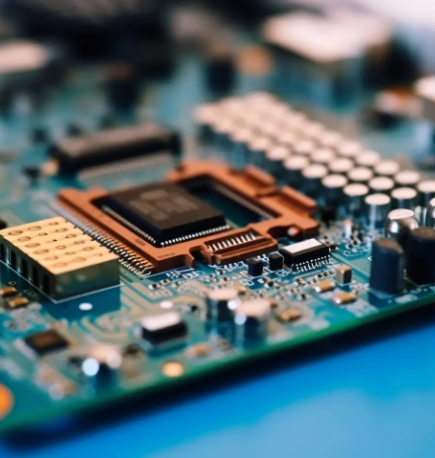

Printed circuit board (PCB) nhyehyɛe yɛ ade titiriw a ɛma wɔyɛ ɛlɛtrɔnik nneɛma. Ɛnyɛ sɛ PCB nhyehyɛe pa betumi ama ɔmansin no adwumayɛ ne ahotoso a ɛwɔ mu no atu mpɔn nko, na mmom ɛbɛtew ɛka a wɔbɔ wɔ nneɛma a wɔyɛ ne nsiesie a ɛyɛ den so nso. Nea edidi so yi yɛ nsɛm ne nsɛm pii a ɛsɛ sɛ wɔde adwene si so wɔ PCB nhyehyɛe mu.

1. Nsusuwii a ɛfa ɔmansin nhyehyɛe ho mfonini ho

Ansa na wobɛtoa PCB nhyehyɛe so no, ɛsɛ sɛ wudi kan wie circuit schematic diagram no nhyehyɛe no. Saa anammɔn yi nyɛ PCB nhyehyɛe no nnyinaso nko, na mmom ɛyɛ nea ɛsɛ sɛ wodi kan yɛ ansa na wɔahwɛ ahu sɛ ɔmansin no yɛ adwuma na ɛyɛ adwuma. Sɛ woreyɛ ɔmansin nhyehyɛe no ho mfonini a, ɛsɛ sɛ wode w’adwene si nsɛm a edidi so yi so:

Ma dwumadie ne ahwehwɛdeɛ mu da hɔ: Te ɔmansin no dwumadie ne adwumayɛ ahwehwɛdeɛ ase pefee na hwɛ sɛ adwini no bɛtumi adi saa ahwehwɛdeɛ yi ho dwuma.

Paw nneɛma a ɛfata: Paw nneɛma a ɛfata a egyina ɔmansin dwumadi so, na wususuw nneɛma te sɛ afã horow no adwumayɛ, nneɛma a wɔde kyekyere nneɛma, ne ɛka ho.

Mark clear logos and parameters: Hwɛ sɛ component logos ne parameters a ɛwɔ schematic diagram no so no mu da hɔ na ɛyɛ pɛpɛɛpɛ na ama PCB nhyehyɛe ne debugging a edi hɔ no ayɛ mmerɛw.

2. Nhyehyɛe a ntease wom

Nteaseɛ mu component nhyehyeɛ yɛ adeɛ a ɛho hia a ɛbɛma PCB ayɛ adwuma. Ɛsɛ sɛ nhyehyɛe no susuw nneɛma pii te sɛ circuit dwumadie, signal integrity, thermal management, ne nea ɛkeka ho ho yie. Nneɛma bi a ɛsɛ sɛ wususuw ho wɔ nhyehyɛe ho ni:

Dwumadi mu mpaepaemu: Kyekyɛ ɔmansin no mu yɛ no module ahorow a ɛyɛ adwuma na fa module koro no ara a ɛyɛ adwuma no afã horow bom ma ɛtew nsɛnkyerɛnne a wɔde fa akwan so no so.

Nsɛnkyerɛnne no mudi mu kura: Ɛsɛ sɛ nsɛnkyerɛnne nhama a ɛde ahoɔhare kɛse kɔ no yɛ tiaa na ɛkɔ tẽẽ sɛnea ɛbɛyɛ yiye biara na wɔakwati sɛ wɔbɛtwetwe wɔn ho. Ɛsɛ sɛ wɔde nsɛnkyerɛnne nhama atitiriw te sɛ dɔn nhama, nhama a wɔde reset, ne nea ɛkeka ho to akyirikyiri fi dede fibea ahorow ho.

Ɔhyew a wɔde di dwuma: Ɛsɛ sɛ wɔkyekyɛ nneɛma a ahoɔden kɛse wom no pɛpɛɛpɛ, ɛsɛ sɛ wosusuw ɔhyew a wɔsɛe no ho nsɛm ho, na sɛ ɛho hia a, ɛsɛ sɛ wɔde radiators anaa ntokuru a ɛma ɔhyew no ka ho.

3. Routing ho mmara

Routing yɛ nkitahodi titiriw foforo wɔ PCB nhyehyɛe mu. Nea edidi so yi yɛ nsɛm bi a ɛsɛ sɛ wohyɛ no nsow bere a woreyɛ routing no:

Line trɛw ne ntam kwan: Paw line trɛw a ɛfata sɛnea mprempren kɛse te na ama woahwɛ ahu sɛ line no betumi agyina mprempren a ɛne no hyia no ano. Ma kwan a ɛfata ntra nsɛnkyerɛnne nhama ahorow ntam na woakwati sɛnkyerɛnne kwan so ntwitwiridii.

Wiring layers dodow: Mpɛn pii no, circuits a ɛyɛ den no hwehwɛ wiring ahorow pii.

Kwati dannan a ɛyɛ nnam: Kwati dannan a ano yɛ nnam bere a worekɔ kwan no, na bɔ mmɔden sɛ wode dannan a ɛyɛ digrii 45 bedi dwuma na ama sɛnkyerɛnne no a ɛdannan ne nea ɛtwetwe adwene no so atew.

4. Tumi a wɔde ma ne asase so nhyehyɛe

Tumi a wɔde ma ne asase so nhyehyɛe ne nneɛma a ɛho hia sen biara wɔ PCB nhyehyɛe mu, a ɛka ɔmansin no gyinabea ne tumi a ɛko tia ntwitwiridii no tẽẽ. Nea edidi so yi ne nneɛma a ɛsɛ sɛ wosusuw ho wɔ tumi ne asase ho nhyehyɛe ho:

Power layer ne ground layer: Fa independent power layer ne ground layer di dwuma na ama impedance a ɛda power supply ne asase ntam no so atew na ama power quality atu mpɔn.

Decoupling capacitor: Hyehyɛ decoupling capacitor wɔ baabi a ɛbɛn tumi pin no na ama dede a ɛyɛ frequency a ɛkɔ soro no afi mu na ama woahwɛ ahu sɛ tumi a wɔde ma no gyina pintinn.

Asase so loop: kwati asase so loop nhyehyeɛ na tew electromagnetic interference so. Ɛsɛ sɛ asase so nhama a wɔde yɛ nsɛnkyerɛnne nhama a ɛho hia no yɛ tiaa na ɛkɔ tẽẽ sɛnea ɛbɛyɛ yiye biara.

5. EMI/EMC nhyehyɛe

Electromagnetic interference (EMI) ne electromagnetic compatibility (EMC) nhyehyeɛ yɛ ade titire a ɛbɛma PCBs ayɛ adwuma yie wɔ electromagnetic mmeaeɛ a ɛyɛ den. Nea edidi so yi yɛ EMI/EMC nhyehyɛe ho nsusuwii:

Shielding design: Shield nsɛnkyerɛnne a ɛyɛ mmerɛw ne nneɛma a ɛyɛ dede kɛse na ama anyinam ahoɔden a ɛtwetwe nneɛma no so atew.

Filter nhyehyɛe: Fa filters ka power supply ne signal lines ho na ama dede signals afi mu na ama electromagnetic compatibility atu mpɔn.

Grounding nhyehyɛe: Grounding nhyehyɛe pa betumi asiw electromagnetic interference ano yiye na ama circuit no tumi a ɛko tia interference no atu mpɔn.

6. Ahwɛyiye a Wɔbɛyɛ wɔ Nneɛma a Wɔyɛ ne Nhyiam Ho

Ɛnsɛ sɛ PCB nhyehyɛe no susuw ɔmansin adwumayɛ nko ho, na mmom ɛsɛ sɛ wosusuw sɛnea ɛbɛyɛ yiye sɛ wɔbɛyɛ ne ne boaboa ano nso ho. Nsɛntitiriw bi a ɛsɛ sɛ wohyɛ no nsow bere a woreyɛ nneɛma na woreboaboa ano no ni:

Component packaging ne spacing: Paw standard packaged components na ama woahwɛ ahu sɛ nhyiam no ntam kwan a ɛdɔɔso a ɛbɛma welding ne nsiesie ayɛ mmerɛw.

Test point design: Hyehyɛ test points wɔ key nodes so na ama circuit sɔhwɛ ne ɔhaw ahorow a edi hɔ no ayɛ mmerɛw.

Nneɛma a wɔyɛ: Te ase na di PCB ayɛfo no nhyehyɛe ho nkyerɛkyerɛmu akyi na ama woahwɛ ahu sɛ nhyehyɛe no di adwinnan no ahwehwɛde ahorow ho dwuma.

sɛ yɛde rewie a

PCB nhyehyeɛ yɛ adeyɛ a ɛyɛ den na ɛyɛ mmerɛw, a ɛfa nneɛma pii te sɛ circuit schematic design, component layout, routing mmara, power supply ne grounding design, EMI/EMC design, manufacturing ne assembly. Afã biara hwehwɛ sɛ adwumfo susuw ho yiye na ama wɔatumi ayɛ ɔmansin board a ɛyɛ adwuma yiye, egyina pintinn na wotumi de ho to so. Ɛnam saa asɛm yi mu nsɛm tiawa so no, mewɔ anidasoɔ sɛ mede nkyerɛkyerɛmu ne akwankyerɛ bi bɛma PCB nhyehyɛɛfoɔ na ama PCB nhyehyɛɛ no ayɛ yie na ayɛ yie.

- 2024-06-21 08:41:41

- Next: Afã horow pii wɔ hɔ a ɛsɛ sɛ wususuw ho bere a woreyɛ PCBA a ɛyɛ pɛ no