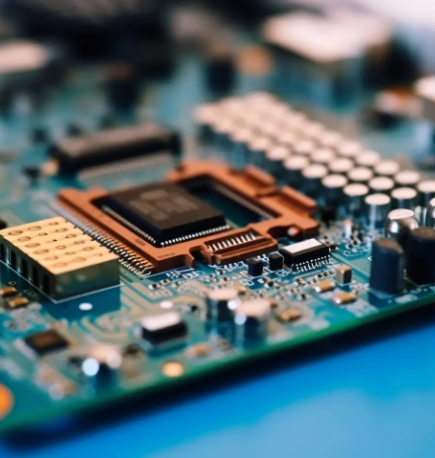

Summary of PCB design points: several things to pay attention to

The design of printed circuit boards (PCBs) is a crucial part of electronic product development. A good PCB design can not only improve the performance and reliability of the circuit, but also reduce production costs and maintenance difficulties. The following are several key points and matters that need to be paid attention to in PCB design.

1. Design of circuit schematic

Before PCB layout, you need to complete the design of the circuit schematic first. This step is not only the basis of PCB design, but also the premise of ensuring the function and performance of the circuit. When designing the circuit schematic, you need to pay attention to the following points:

Clarify functions and requirements: Clearly understand the functional and performance requirements of the circuit and ensure that the design can meet these requirements.

Choose appropriate components: Choose appropriate components according to the circuit function, considering factors such as component performance, packaging, and cost.

Mark clear logos and parameters: Ensure that the component logos and parameters on the schematic are clear and accurate to facilitate subsequent PCB layout and debugging.

2. Reasonable layout

Reasonable component layout is an important part of ensuring PCB performance. Layout needs to consider circuit function, signal integrity, thermal management and other aspects. Here are some layout considerations:

Functional partitioning: Divide the circuit into functional modules and place the components of the same functional modules together to reduce the signal transmission path.

Signal integrity: High-speed signal lines should be as short and direct as possible to avoid cross-interference. Key signal lines such as clock lines and reset lines should be kept away from noise sources.

Thermal management: High-power components should be evenly distributed, and heat dissipation should be considered. If necessary, add heat sinks or heat dissipation holes.

3. Routing rules

Routing is another key link in PCB design. Reasonable routing can avoid signal interference and transmission delay. Here are a few points to note when routing:

Line width and spacing: Choose the appropriate line width according to the current size to ensure that the line can withstand the corresponding current. Keep enough spacing between different signal lines to avoid signal interference.

Number of wiring layers: Complex circuits usually require multiple layers of wiring. The wiring of each layer should be arranged reasonably to ensure good distribution of signal lines and power lines.

Avoid sharp turns: Avoid sharp turns when routing, and try to use 45-degree angle turns to reduce signal reflection and interference.

4. Power supply and grounding design

Power supply and grounding design are the top priorities of PCB design, which directly affect the stability and anti-interference ability of the circuit. The following are the precautions for power supply and grounding design:

Power layer and ground layer: Use independent power layer and ground layer to reduce the impedance between power and ground and improve power quality.

Decoupling capacitor: Place decoupling capacitors near the power pins to filter out high-frequency noise and ensure power supply stability.

Ground loop: Avoid ground loop design to reduce electromagnetic interference. The ground wire of key signal lines should be as short and direct as possible.

5. EMI/EMC design

Electromagnetic interference (EMI) and electromagnetic compatibility (EMC) design are the key to ensure that PCB works properly in a complex electromagnetic environment. The following are the considerations for EMI/EMC design:

Shielding design: Shield sensitive signals and high-noise components to reduce electromagnetic interference.

Filter design: Add filters to power and signal lines to filter out noise signals and improve electromagnetic compatibility.

Grounding design: A good grounding design can effectively suppress electromagnetic interference and improve the circuit's anti-interference ability.

6. Manufacturing and assembly considerations

PCB design should not only consider circuit performance, but also the feasibility of manufacturing and assembly. The following are some points to pay attention to during manufacturing and assembly:

Component packaging and spacing: Select components with standard packaging and ensure sufficient assembly spacing to facilitate welding and maintenance.

Test point design: Arrange test points at key nodes to facilitate subsequent circuit testing and troubleshooting.

Production process: Understand and follow the process specifications of the PCB manufacturer to ensure that the design meets manufacturing requirements.

in conclusion

PCB design is a complex and delicate process, involving circuit schematic design, component layout, routing rules, power supply and grounding design, EMI/EMC design, manufacturing and assembly, etc. Each link requires the designer to consider it in detail in order to design a circuit board with excellent performance, stability and reliability. Through the summary of this article, I hope to provide some reference and guidance for PCB designers to improve the quality and efficiency of PCB design.

- 2024-06-21 09:29:42

- Next: Designing a perfect PCBA requires considering multiple aspects