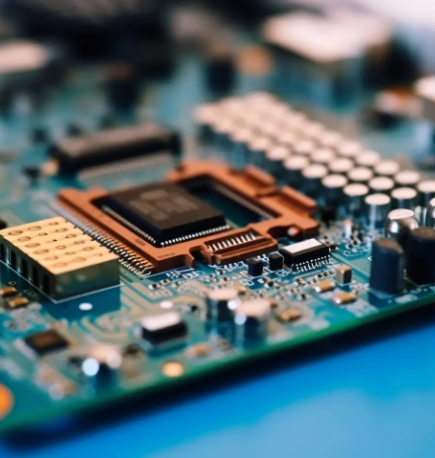

Designing a perfect PCBA requires considering multiple aspects

Designing a perfect PCBA (Printed Circuit Board Assembly) requires consideration of many aspects, from circuit design to component selection, to production and testing. The following are some of the difficulties and key points in PCBA design and how to achieve a perfect design.

1. Difficulties in PCBA Design

Circuit complexity: Modern electronic products are becoming more and more powerful, which makes circuit design more complex. Multilayer boards, high-speed signals, mixed signals (analog and digital), etc. will increase the difficulty of design.

Thermal management: High-power components will generate a lot of heat. If the heat cannot be effectively dissipated, the PCBA performance will be degraded or even fail.

Electromagnetic compatibility (EMC): Electronic equipment needs to meet various electromagnetic compatibility standards, and electromagnetic interference (EMI) and electromagnetic susceptibility (EMS) need to be controlled during design.

Space limitation: Especially in miniaturized electronic products, the PCB area is limited, and it is a challenge to arrange components and traces within the limited space.

Manufacturing process: Different manufacturing processes have different design requirements, such as the combination of surface mount technology (SMT) and through-hole technology (THT).

Cost control: Under the premise of ensuring performance and quality, how to control costs is also a major difficulty in design.

2. Key points of PCBA design

Clear design requirements: Before designing, clarify the product's functional requirements, performance indicators, environmental requirements, etc. Understand customer needs and industry standards to ensure that the design meets expectations.

Reasonable circuit design: Choose the appropriate circuit topology, reasonably distribute power and ground wires, and ensure signal integrity. For complex circuits, simulation software can be used for verification.

Component selection: Select components with high reliability and stable performance, and consider their supply chain. Pay attention to the power consumption and thermal management of components.

PCB layout and routing:

Layout: Arrange components reasonably, considering signal paths, power distribution, and heat dissipation paths. Key components and sensitive circuits should be arranged first.

Wiring: Partition according to circuit function to ensure reasonable distribution of high-speed signals, analog signals, and digital signals. Pay attention to the length and width of the traces and avoid too many vias.

Power management: Design a stable power system to ensure that each module receives the appropriate power supply. Use filter capacitors and power distribution networks (PDNs) to optimize power quality.

Heat dissipation design: For heat-generating components, design appropriate heat dissipation solutions, such as adding heat dissipation copper foil, using heat sinks or fans, etc. Ensure that the overall heat distribution of the PCB is uniform.

3. How to design a perfect PCBA

Preliminary preparation:

Understand project requirements in detail and write complete design specifications.

Communicate with related departments (e.g. mechanical design, software development, manufacturing engineering) to ensure the manufacturability and testability of the design.

Develop design plans and timelines to ensure projects are completed on time.

Circuit Design and Simulation:

Use professional EDA software for circuit design to ensure that the design meets the specifications.

Simulate and verify key circuits to identify and resolve potential problems in advance.

PCB layout and routing:

Perform PCB layout and routing in EDA software, paying attention to signal integrity and power integrity.

Use a combination of automatic routing and manual adjustments to optimize PCB design.

Design review and optimization:

Conduct design review and invite experts from various parties to participate in checking the correctness and rationality of the design.

Optimize based on review comments, with special attention to signal integrity, power integrity, and thermal design.

Prototype production and testing:

Make samples and conduct functional tests, performance tests and environmental tests to verify the reliability and stability of the design.

Analyze and improve the problems found in the test, and redesign if necessary.

Preparation for mass production:

After confirming that the sample has passed the test, prepare for mass production and communicate with the manufacturer to ensure that there will be no problems during the mass production process.

Develop a detailed test plan to ensure that each PCBA is rigorously tested and meets quality requirements.

keep improve:

Collect feedback information after mass production, analyze common problems, and make continuous improvements.

Regularly evaluate design and manufacturing processes to optimize production efficiency and quality control.

By strictly following these steps and key points, we can effectively deal with the difficulties in PCBA design and design high-quality, high-performance PCBAs to meet the needs of customers and the market.

- Pre: Summary of PCB design points: several things to pay attention to

- 2024-07-09 20:22:25