Sɔma fɔ PCB dizayn ki pɔynt dɛn: sɔm tin dɛn fɔ pe atɛnshɔn to

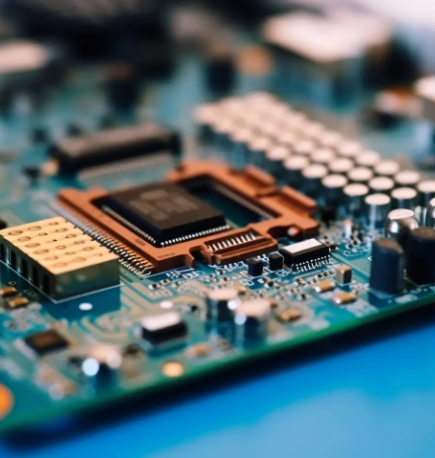

Dizayn we dɛn mek fɔ print sɛrkyut bɔd (PCB) na impɔtant tin fɔ mek dɛn ebul fɔ mek ilɛktronik prɔdak dɛn. Wan gud PCB dizayn nɔ kin jɔs mek di sɔrkwit wok ɛn rilaybiliti, bɔt i kin ridyus di kɔst fɔ prodakshɔn ɛn di difikulti fɔ mentenɛns. Dis na sɔm pɔynt ɛn tin dɛn we dɛn nid fɔ pe atɛnshɔn to we dɛn de mek PCB.

1. Disain fɔ sɔrkwit skematik dayagram

Bifo yu go bifo wit PCB layout, yu fɔs nid fɔ kɔmplit di dizayn fɔ di sɔrkwit skematik dayagram. Dis step nɔto jɔs di besis fɔ PCB dizayn, bɔt na di prɛrikuls fɔ mek shɔ se sɔrkwit de wok ɛn pefɔmɛns. We yu de disayn di sɛktri skematik dayagram, yu nid fɔ pe atɛnshɔn to dɛn pɔynt dɛn ya:

Klarify di wok ɛn rikwaymɛnt dɛn: Ɔndastand klia wan di wok ɛn pefɔmɛns rikwaymɛnt dɛn fɔ di sɔrkwit ɛn mek shɔ se di dizayn ebul fɔ mit dɛn rikwaymɛnt dɛn ya.

Pik di kɔmpɔnɛnt dɛn we fit: Pik di kɔmpɔnɛnt dɛn we fit bay di we aw di sɔrkwit de wok, ɛn tek tɛm tink bɔt tin dɛn lɛk di we aw di kɔmpɔnɛnt dɛn de wok, di we aw dɛn pak am, ɛn di kɔst.

Mak klia logo ɛn paramita dɛn: Mek shɔ se di kɔmpɔnɛnt logo ɛn paramita dɛn na di skematik dayagram klia ɛn kɔrɛkt fɔ mek i izi fɔ mek di PCB layout ɛn dibɔg we go kam afta dat.

2. Rizin layout

Rizin komponent layout na impɔtant pat fɔ mek shɔ se PCB pefɔmɛns. Di layout nid fɔ kɔmprɛhnsiv wan tink bɔt bɔku aspek dɛn lɛk sɔrkwit fɛnshɔn, signal intɛgriti, tɛmal manejmɛnt, ɛn ɔda tin dɛn. Na sɔm layout tin dɛn we yu fɔ tink bɔt:

Fɔnshɔnal patishɔn: Divayd di sɔrkwit insay fɛnshɔnal mɔdyul dɛn ɛn put kɔmpɔnɛnt dɛn fɔ di sem fɛnshɔnal mɔdyul dɛn togɛda fɔ ridyus di signal transmishɔn pat dɛn.

Signal integriti: Di signal layn dɛn we de spid fɔ shɔt ɛn dairekt as i pɔsibul fɔ mek dɛn nɔ gɛt krɔs intafɛreshɔn. Ki signal layn dɛn lɛk klok layn dɛn, riset layn dɛn, ɛn ɔda tin dɛn fɔ de fa frɔm say dɛn we nɔys de.

Tɛmral manejmɛnt: Dɛn fɔ sheb di komponent dɛn we gɛt ay pawa ivin, dɛn fɔ tink bɔt tin dɛn we gɛt fɔ du wit di we aw di ɔt de pwɛl, ɛn dɛn fɔ ad redyuta ɔ ol dɛn we de mek di ɔt nɔ de igen if nid de.

3. Di lɔ dɛn bɔt aw fɔ mek rod

Routing na ɔda ki link na PCB dizayn Rizin routing kin avɔyd signal intafɛreshɔn ɛn transmishɔn dilɛys. Na sɔm tin dɛn we yu fɔ no we yu de rout:

Layn wit ɛn spɛshal say: Pik di rayt layn wit akɔdin to di saiz we de naw fɔ mek shɔ se di layn ebul fɔ bia wit di kɔrɛnt we kɔrɛkt. Mentɛn inof spays bitwin difrɛn signal layn dɛn fɔ avɔyd signal intafɛreshɔn.

Nɔmba fɔ di waya layers: Kɔmpleks sɔrkwit dɛn kin nid fɔ gɛt mɔlti-layer waya.

Avɔyd shap tɔn: Nɔ shap tɔn we yu de rout, ɛn tray fɔ yuz 45-digri oblique tɔn fɔ ridyus signal riflɛkshɔn ɛn intafɛreshɔn.

4. Pawa saplai ɛn grɔn dizayn

Pawa saplai ɛn grɔndin dizayn na di tɔp prayorities fɔ PCB dizayn, we de afɛkt di stebiliti ɛn anti-intafɛreshɔn abiliti fɔ di sɔrkwit dairekt wan. Dis na tin dɛn we yu fɔ tink bɔt fɔ di pawa ɛn grɔn dizayn:

Pawa layt ɛn grɔn layt: Yuz indipɛndɛnt pawa layt ɛn grɔn layt fɔ ridyus di impedans bitwin pawa saplai ɛn grɔn ɛn fɔ mek di pawa kwaliti bɛtɛ.

Dikɔpl kapasitɔ: Arenj dikɔpl kapasitɔ nia di pawa pin fɔ filta ɔut ay-frikyuɛnsi nɔys ɛn mek shɔ se di pawa saplai stebul.

Grɔn lɔp: avɔyd grɔn lɔp dizayn ɛn ridyus ilɛktromagnetik intafɛreshɔn. Grɔn waya fɔ krichɔ signal layn dɛn fɔ shɔt ɛn dairekt as pɔsibul.

5. EMI/EMC dizayn

Ilɛktromagnetik intafɛreshɔn (EMI) ɛn ilɛktromagnetik kɔmpatibiliti (EMC) dizayn na di men tin fɔ mek shɔ se PCB dɛn de wok fayn fayn wan na kɔmpleks ilɛktromagnetik ɛnvayrɔmɛnt dɛn. Dis na EMI/EMC dizayn kɔnsidareshɔn dɛn:

Shild dizayn: Shild sɛnsitiv signal ɛn ay-nɔys kɔmpɔnɛnt dɛn fɔ ridyus ilɛktromagnetik intafɛreshɔn.

Filta dizayn: Ad filta to di pawa saplai ɛn signal layn fɔ filta ɔut nɔys signal ɛn impruv ilɛktromagnetik kɔmpatibiliti.

Grɔndin dizayn: Gud grɔndin dizayn kin ebul fɔ stɔp ilɛktromagnetik intafɛreshɔn fayn fayn wan ɛn impruv di anti-intafɛreshɔn abiliti fɔ di sɔrkwit.

6. Di tin dɛn we dɛn fɔ tek tɛm wit we dɛn de mek ɛn asembl

PCB dizayn nɔ fɔ jɔs tink bɔt di sɔrkwit pefɔmɛns, bɔt i fɔ tink bak bɔt di fisibiliti fɔ mek ɛn asɛmbli. Na sɔm tin dɛn we yu fɔ no we yu de mek ɛn gɛda:

Komponent pak ɛn spays: Pik standad pak komponent fɔ mek shɔ se inɔf asɛmbli spɛshal fɔ mek i izi fɔ wɛldin ɛn mentenɛns.

Test poɛnt dizayn: Arenj tɛst pɔynt dɛn na di ki no dɛm fɔ mek i izi fɔ tɛst sɔrkwit ɛn sɔlv prɔblɛm dɛn afta dat.

Prodakshɔn prɔses: Ɔndastand ɛn fala di prɔses spɛsifikɛshɔn dɛn fɔ di PCB manifakta dɛn fɔ mek shɔ se di dizayn mit di manufakchurin rikwaymɛnt dɛn.

fɔ dɔn

PCB dizayn na kɔmpleks ɛn dilik prɔses, we involv bɔku aspek dɛn lɛk sɔrkwit skematik dizayn, kɔmpɔnɛnt layout, routin lɔ dɛn, pawa saplai ɛn grɔndin dizayn, EMI/EMC dizayn, manufakchurin ɛn asɛmbli. Ɛvri aspek nid fɔ tek tɛm tink bɔt di disayna dɛn fɔ mek dɛn ebul fɔ disayn wan sɔrkwit bɔd wit fayn fayn wok, stebiliti ɛn rilibiliti. Tru di sɔmari fɔ dis atikul, a op fɔ gi sɔm rɛfrɛns ɛn gayd fɔ PCB disayna dɛn fɔ mek di kwaliti ɛn efyushɔn fɔ PCB dizayn bɛtɛ.

- 2024-06-21 08:36:03

- Next: Bɔku tin dɛn de we yu fɔ tink bɔt we yu de disayn di pafɛkt PCBA