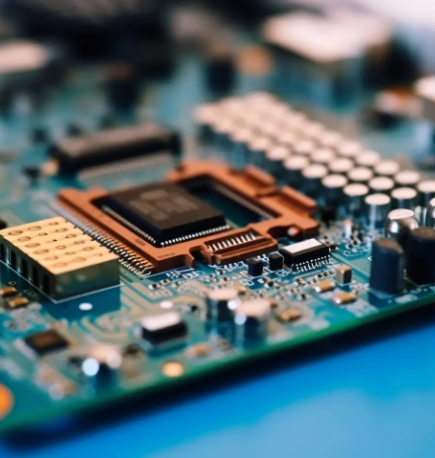

Bɔku tin dɛn de we yu fɔ tink bɔt we yu de disayn di pafɛkt PCBA

Fɔ disayn wan pafɛkt PCBA (Printed Circuit Board Assembly) nid fɔ tink bɔt bɔku tin dɛn, frɔm di sakit dizayn to di kɔmpɔnɛnt sɛlɛkshɔn, to prodakshɔn ɛn tɛst. Dis na sɔm prɔblɛm dɛn, di men pɔynt dɛn na PCBA dizayn ɛn di we dɛn fɔ ajɔst pafɛkt dizayn.

1. Difikulti dɛn na PCBA dizayn

Sakit Kɔmplisiti: Di ilɛktronik tin dɛn we dɛn de yuz tide de gɛt mɔ ɛn mɔ pawa, ɛn dis de mek dɛn de mek kɔmpleks sakit dizayn dɛn. Bɔku layers bod dɛn, ay-spid signal dɛn, miks signal dɛn (analɔg ɛn dijital), ɛn ɔda tin dɛn go mek i nɔ izi fɔ dizayn.

Tɛmral manejmɛnt: Di kɔmpɔnɛnt dɛn we gɛt ay pawa go mek bɔku ɔt If di ɔt nɔ go ebul fɔ pul di ɔt fayn fayn wan, i go mek PCBA pefɔmɛns pwɛl ɔ i go pwɛl.

Ilɛktromagnetik kɔmpatibiliti (EMC): Ilɛktronik ikwipmɛnt nid fɔ mit difrɛn ilɛktromagnetik kɔmpatibiliti standad dɛn, ɛn ilɛktromagnetik intafɛreshɔn (EMI) ɛn ilɛktromagnetik susɛptibiliti (EMS) nid fɔ kɔntrol insay di dizayn.

Spays limiteshɔn: Ɛspɛshali insay miniaturized ilɛktronik prodak, di PCB eria limited, ɛn aw fɔ arenj komponent ɛn trays na di limited spes na chalenj.

Manufakchurin prɔses: Difrɛn manufakchurin prɔses dɛn gɛt difrɛn rikwaymɛnt fɔ dizayn, lɛk di kɔmbaynshɔn fɔ sɔfayz mawnt tɛknɔlɔji (SMT) ɛn tru-hol teknɔlɔji (THT).

Kɔst kɔntrol: Pan di premis fɔ mek shɔ se dɛn de du di wok ɛn kwaliti, aw fɔ kɔntrol di kɔst na big prɔblɛm bak fɔ dizayn.

2. Ki pɔynt dɛn fɔ PCBA dizayn

Klia dizayn rikwaymɛnt: Bifo yu disayn, klarify di funkshɔn rikwaymɛnt, pefɔmɛns indikɛtɔ, envayrɔmɛnt rikwaymɛnt, ɛn ɔda tin dɛn fɔ di prɔdak. Ɔndastand wetin di kɔstɔma dɛn nid ɛn di standad dɛn we di industri gɛt fɔ mek shɔ se dizayn dɛn mit wetin dɛn de op fɔ.

Rizinal sɔrkwit dizayn: Pik di rayt sɔrkwit tɔpɔlɔji, rizinɔs fɔ sheb pawa ɛn grɔn waya, ɛn mek shɔ se signal intɛgriti. Fɔ kɔmpleks sɔrkwit, dɛn kin yuz simulshɔn softwe fɔ verify.

Kɔmpɔnɛnt sɛlɛkshɔn: Pik kɔmpɔnɛnt dɛn we gɛt ay rilaybiliti ɛn stebul pefɔmɛns, ɛn tink bɔt dɛn sapɔt chen kɔndishɔn. Pe atɛnshɔn to kɔmpɔnɛnt pawa kɔnsɔmshɔn ɛn tɛmral manejmɛnt.

PCB layout ɛn routin:

Layout: Arenj kɔmpɔnɛnt dɛn rizinɔs wan, tek kɔnt ɔf signal pat, pawa distribyushɔn ɛn ɔt disipeshɔn pat. Ki komponent ɛn sɛnsitiv sɔrkwit dɛn fɔ bi di fɔs tin.

Wayring: Patishɔn akɔdin to di sɔrkwit fɛnshɔn fɔ mek shɔ se dɛn de sheb di ay-spid signal dɛn, analɔg signal dɛn ɛn dijital signal dɛn fayn fayn wan. Pe atɛnshɔn to di lɔng ɛn waid fɔ di trays ɛn avɔyd tumɔs via.

Pawa manejmɛnt: Disain wan stebul pawa sistem fɔ mek shɔ se ɛni mɔdyul gɛt di rayt pawa. Optimayz pawa kwaliti yuz filta kapasitɔ ɛn pawa distribyushɔn nɛtwɔk (PDN).

Dizayn fɔ disayp di ɔt: Fɔ di kɔmpɔnɛnt dɛn we de mek di ɔt, disayn di rayt sɔlvishɔn fɔ disaypul ɔt, lɛk fɔ ad kɔpa fɔyl we de mek di ɔt, yuz ɔt sink ɔ fan, ɛn ɔda tin dɛn. Mek shɔ se di ɔt distribyushɔn yunifom ɔlsay na di PCB.

3. Aw fɔ disayn wan pafɛkt PCBA

Fɔ pripia fɔs:

Ɔndastand di prɔjek rikwaymɛnt dɛn ditayli ɛn rayt kɔmplit dizayn spɛsifikɛshɔn dɛn.

Kɔmyuniket wit dipatmɛnt dɛn we gɛt fɔ du wit am (e.g. mɛkanikal dizayn, sɔftwɛl divɛlɔpmɛnt, manufakchurin injinɛri) fɔ mek shɔ se dizayn manufakchurabiliti ɛn tɛstabiliti.

Divɛlɔp dizayn plan ɛn tɛmlayn fɔ mek shɔ se dɛn dɔn di prɔjek dɛn di rayt tɛm.

Dizayn ɛn simulshɔn fɔ di sakit:

Yuz profeshɔnal EDA softwe fɔ sɛrkyut dizayn fɔ mek shɔ se di dizayn de fala di spɛsifikɛshɔn dɛn.

Kɔndɔkt simulshɔn verifyeshɔn pan ki sɔrkwit fɔ diskɔba ɛn sɔlv prɔblɛm dɛn we kin apin bifo tɛm.

PCB layout ɛn routin:

Pɔfɔm PCB layout ɛn routin insay EDA softwe, pe atɛnshɔn to signal intɛgriti ɛn pawa intɛgriti.

Yuz wan kɔmbaynshɔn fɔ ɔtomɛtik routin ɛn manual ajɔstmɛnt fɔ ɔptimayz PCB dizayn.

Disain rivyu ɛn ɔptimayzeshɔn:

Kɔndɔkt dizayn rivyu ɛn invayt bɔku masta sabi pipul dɛn fɔ tek pat fɔ chɛk if di dizayn kɔrɛkt ɛn i mek sɛns.

Optimayz bays pan rivyu kɔmɛnt, pe spɛshal atɛnshɔn to signal intɛgriti, pawa intɛgriti, ɛn tɛmal dizayn.

Prototayp prodakshɔn ɛn tɛst:

Mek protɔtayp, kɔndɔkt fɛnshɔnal tɛst, pefɔmɛns tɛst ɛn envayrɔmɛnt tɛst fɔ chɛk di rilaybiliti ɛn stebiliti fɔ di dizayn.

Analayz ɛn impruv di prɔblɛm dɛn we dɛn fɛn we dɛn de tɛst, ɛn ridizayn if nid de.

Pripia fɔ mas prodakshɔn:

Afta yu dɔn kɔnfyus se di protɔtayp tɛst dɔn pas, rɛdi fɔ mas prodakshɔn. Kɔmyuniket wit di wan dɛn we de mek am fɔ mek shɔ se no prɔblɛm nɔ go apin we dɛn de mek bɔku bɔku tin dɛn.

Divɛlɔp wan ditayl tɛst plan fɔ mek shɔ se dɛn tɛst ɛni PCBA strɔng wan ɛn mit di kwaliti rikwaymɛnt dɛn.

kip impɔtant:

Kɔlekt fidbak infɔmeshɔn afta mas prodakshɔn, analayz kɔmɔn prɔblɛm dɛn, ɛn mek kɔntinyu fɔ impɔtant.

Ɔltɛm, dɛn kin ebul fɔ evaluate dizayn ɛn manufakchurin prɔses fɔ mek di prodakshɔn efyushɔn ɛn kwaliti kɔntrol bɛtɛ.

We yu fala dɛn step ya ɛn di men pɔynt dɛn strikt wan, yu kin ebul fɔ dil fayn fayn wan wit di prɔblɛm dɛn we de na PCBA dizayn, disayn ay kwaliti, supiriɔ-pɔfɔmɛnshɔn PCBA, ɛn mit di nid dɛn fɔ di kɔstɔma dɛn ɛn di makit.

- Pre: Sɔma fɔ PCB dizayn ki pɔynt dɛn: sɔm tin dɛn fɔ pe atɛnshɔn to

- 2024-07-09 20:27:19