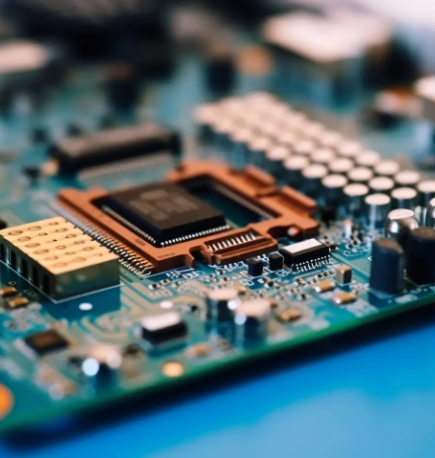

Isifinyezo se-PCB design amaphuzu abalulekile: izinto ezimbalwa okufanele uzinake

Idizayini yebhodi lesifunda ephrintiwe (PCB) iyisixhumanisi esibalulekile ekuthuthukisweni komkhiqizo we-elekthronikhi. Umklamo omuhle we-PCB awukwazi nje ukuthuthukisa ukusebenza nokuthembeka kwesifunda, kodwa futhi unciphise izindleko zokukhiqiza nobunzima bokulungisa. Okulandelayo amaphuzu amaningana nezindaba ezidinga ukunakwa ekwakhiweni kwe-PCB.

1. Idizayini ye-circuit schematic diagram

Ngaphambi kokuqhubeka nesakhiwo se-PCB, okokuqala udinga ukuqedela ukuklama komdwebo womdwebo wesifunda. Lesi sinyathelo akusona nje isisekelo sokuklama kwe-PCB, kodwa futhi siyisidingo sokuqinisekisa umsebenzi wesifunda nokusebenza. Lapho uklama umdwebo we-circuit schematic, udinga ukunaka amaphuzu alandelayo:

Cacisa imisebenzi nezimfuneko: Ziqonde ngokucacile izimfuneko zokusebenza nokusebenza kwesekethe futhi uqinisekise ukuthi umklamo ungahlangabezana nalezi zidingo.

Khetha izingxenye ezifanele: Khetha izingxenye ezifanele ngokusekelwe emisebenzini yesekethe, ucabangele izici ezifana nokusebenza kwengxenye, ukupakisha, kanye nezindleko.

Maka amalogo acacile namapharamitha: Qinisekisa ukuthi amalogo nezinhlaka zengxenye kumdwebo wohlelo zicacile futhi zinembile ukuze wenze kube lula ukwakheka kwe-PCB nokulungisa iphutha.

2. Isakhiwo esinengqondo

Isakhiwo sengxenye enengqondo siyingxenye ebalulekile yokuqinisekisa ukusebenza kwe-PCB. Isakhiwo sidinga ukucabangela ngokugcwele izici eziningi ezifana nomsebenzi wesekethe, ubuqotho besignali, ukuphathwa kwe-thermal, njll. Nazi ezinye izinto zokucatshangelwa kwesakhiwo:

Ukwahlukanisa okusebenzayo: Hlukanisa umjikelezo ube amamojula asebenzayo futhi ubeke izingxenye zamamojula afanayo asebenzayo ndawonye ukuze unciphise izindlela zokudlulisa isignali.

Ubuqotho besignali: Imigqa yesignali yesivinini esiphezulu kufanele ibe mifushane futhi iqonde ngangokunokwenzeka ukuze kugwenywe ukuphazamiseka okuphambene. Imigqa yesignali engukhiye njengelayini yewashi, imigqa yokusetha kabusha, njll. kufanele igcinwe kude nemithombo yomsindo.

Ukuphathwa kwe-thermal: Izingxenye zamandla aphezulu kufanele zisakazwe ngokulinganayo, futhi izindaba zokukhipha ukushisa kufanele zicatshangelwe Uma kunesidingo, ama-radiator noma izimbobo zokushisa kufanele zengezwe.

3. Imithetho yomzila

Umzila ngesinye isixhumanisi esiyinhloko ekwakhiweni kwe-PCB okuphusile kungagwema ukuphazamiseka kwesignali nokubambezeleka kokudlulisela. Nawa amaphuzu okufanele uwaqaphele lapho uthatha umzila:

Ububanzi bomugqa nesikhala: Khetha ububanzi bomugqa obufanele ngokosayizi wamanje ukuze uqinisekise ukuthi umugqa ungamelana namandla ahambisanayo. Gcina isikhala esanele phakathi kwemigqa yesignali eyahlukene ukuze ugweme ukuphazamiseka kwesignali.

Inombolo yezendlalelo zezintambo: Amasekhethi ayinkimbinkimbi ngokuvamile adinga izintambo ezinezingqimba eziningi ukuhlela ngokunengqondo izintambo zongqimba ngalunye ukuze kuqinisekiswe ukusatshalaliswa okuhle kwemigqa yesignali nezintambo zamandla.

Gwema ukujika okubukhali: Gwema ukujika okubukhali lapho uzulazula, futhi uzame ukusebenzisa ukujika kwe-oblique okungu-45-degree ukuze unciphise ukubonakaliswa kwesignali nokuphazamiseka.

4. Ukunikezwa kwamandla kanye nomklamo ophansi

Ukunikezwa kwamandla kanye nomklamo ophansi yizinto eziza kuqala kumklamo we-PCB, othinta ngokuqondile ukuzinza kanye nekhono lokulwa nokuphazamiseka kwesekethe. Okulandelayo ukucatshangelwa kwamandla kanye nokwakhiwa komhlabathi:

Isendlalelo samandla nesendlalelo saphansi: Sebenzisa ungqimba lwamandla ozimele kanye nongqimba lwaphansi ukuze unciphise ukuthintana phakathi kokunikezwa kwamandla nomhlabathi futhi uthuthukise ikhwalithi yamandla.

I-Decoupling capacitor: Hlela i-decoupling capacitor eduze nephinikhodi ukuze uhlunge umsindo we-high-frequency futhi uqinisekise ukuqina kokunikezwa kwamandla.

I-Ground loop: gwema ukwakheka kwe-loop yomhlabathi futhi unciphise ukuphazamiseka kwe-electromagnetic. Izintambo eziphansi zemigqa yesignali ebalulekile kufanele zibe zifushane futhi ziqonde ngangokunokwenzeka.

5. EMI/EMC design

I-Electromagnetic interference (EMI) kanye ne-electromagnetic comppatibility (EMC) idizayini iyisihluthulelo sokuqinisekisa ukuthi ama-PCB asebenza kahle ezindaweni eziyinkimbinkimbi zikamagnetic. Okulandelayo ukucatshangelwa kokuklama kwe-EMI/EMC:

Idizayini yesivikelo: Vikela amasiginali azwelayo nezinto ezinomsindo omkhulu ukuze unciphise ukuphazamiseka kukazibuthe.

Idizayini yesihlungi: Engeza izihlungi kumandla kagesi nemigqa yesignali ukuze uhlunge amasiginali womsindo futhi uthuthukise ukuhambisana kwe-electromagnetic.

Idizayini yokubeka phansi: Idizayini enhle yokubeka phansi ingacindezela ngempumelelo ukuphazamiseka kukagesi futhi ithuthukise ikhono lokulwa nokuphazamiseka kwesekethe.

6. Izinyathelo Zokukhiqiza kanye NezoMkhandlu

Umklamo we-PCB akufanele ucabangele ukusebenza kwesifunda kuphela, kodwa futhi nokuba nokwenzeka kokukhiqiza nokuhlanganisa. Nawa amaphuzu okufanele uwaqaphele lapho kukhiqizwa futhi kuhlanganiswa:

Ukupakishwa kwezingxenye kanye nesikhala: Khetha izingxenye ezipakishiwe ezijwayelekile ukuze uqinisekise isikhala esanele sokuhlanganisa ukuze kube lula ukushisela nokulungisa.

Idizayini yephoyinti lokuhlola: Hlela amaphuzu okuhlola kumanodi angukhiye ukuze uqhubekisele phambili ukuhlolwa kwesifunda nokuxazulula izinkinga.

Inqubo yokukhiqiza: Qonda futhi ulandele imininingwane yenqubo yabakhiqizi be-PCB ukuze uqinisekise ukuthi umklamo uhlangabezana nezidingo zokukhiqiza.

Ekuphetheni

Idizayini ye-PCB iyinqubo eyinkimbinkimbi nentekenteke, ehlanganisa izici eziningi ezifana nomklamo wohlelo lwesekethe, ukwakheka kwengxenye, imithetho yomzila, ukunikezwa kwamandla kanye nomklamo ophansi, umklamo we-EMI/EMC, ukukhiqiza nokuhlanganisa. Zonke izici zidinga ukucatshangelwa ngokucophelela ngabaklami ukuze bakhe ibhodi lesifunda elinomsebenzi omuhle kakhulu, ukuzinza nokuthembeka. Ngesifinyezo salesi sihloko, ngithemba ukuhlinzeka ngereferensi nesiqondiso kubaklami be-PCB ukuze bathuthukise ikhwalithi nokusebenza kahle komklamo we-PCB.

- 2024-06-21 08:42:39

- Next: Kunezici eziningi okufanele uzicabangele lapho uklama i-PCBA ephelele