Kunezici eziningi okufanele uzicabangele lapho uklama i-PCBA ephelele

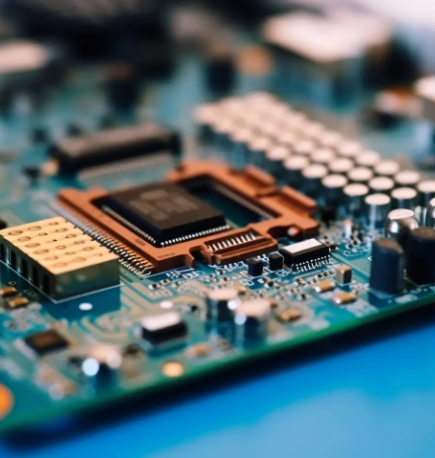

Ukuklama i-PCBA ephelele (I-Printed Circuit Board Assembly) idinga ukucabangela izici eziningi, kusukela ekwakhiweni kwesifunda ukuya ekukhethweni kwengxenye, ekukhiqizeni nasekuhlolweni. Okulandelayo ubunzima obuthile, amaphuzu abalulekile ekwakhiweni kwe-PCBA nezindlela zokufeza ukuklama okuphelele.

1. Ubunzima ekwakhiweni kwe-PCBA

I-Circuit Complexity: I-electronics yesimanje iya ngokuya iba namandla, okuholela emiklamo eyinkimbinkimbi yesekethe. Amabhodi amaningi, amasignali anesivinini esikhulu, amasignali axubile (i-analog nedijithali), njll. konke kuzokwandisa ubunzima bomklamo.

Ukuphatha okushisayo: Izingxenye zamandla aphezulu zizokhiqiza ukushisa okuningi Uma ukushisa kungakwazi ukuchithwa ngokuphumelelayo, kuzobangela ukuwohloka kokusebenza kwe-PCBA noma ukwehluleka.

Ukuhambisana kwe-Electromagnetic (EMC): Imishini kagesi idinga ukuhlangana namazinga ahlukahlukene wokuhambisana kuka-electromagnetic, kanye nokuphazanyiswa kuka-electromagnetic (EMI) kanye ne-electromagnetic susceptibility (EMS) kudinga ukulawulwa ekwakhiweni.

Imikhawulo yesikhala: Ikakhulukazi emikhiqizweni ye-elekthronikhi emincane, indawo ye-PCB inomkhawulo, futhi ukuthi uhlela kanjani izingxenye kanye nokulandela umkhondo endaweni elinganiselwe kuyinselele.

Inqubo yokukhiqiza: Izinqubo ezihlukene zokukhiqiza zinezidingo ezihlukene zokuklama, njengenhlanganisela yobuchwepheshe bokukhweza komhlabathi (SMT) kanye nobuchwepheshe be- through-hole (THT).

Ukulawulwa kwezindleko: Ngokwesisekelo sokuqinisekisa ukusebenza kanye nekhwalithi, indlela yokulawula izindleko nakho kuwubunzima obukhulu ekwakhiweni.

2. Amaphuzu abalulekile we-PCBA design

Sula izidingo zokuklama: Ngaphambi kokuklama, cacisa izidingo zokusebenza, izinkomba zokusebenza, izidingo zemvelo, njll. zomkhiqizo. Qonda izidingo zamakhasimende kanye namazinga omkhakha ukuze uqinisekise ukuthi imiklamo ihlangabezana nokulindelwe.

Idizayini yesekethe enengqondo: Khetha i-topology yesekethe efanele, sabalalisa ngokunengqondo izintambo zamandla nezaphansi, futhi uqinisekise ubuqotho besignali. Kumasekhethi ayinkimbinkimbi, isoftware yokulingisa ingasetshenziselwa ukuqinisekiswa.

Ukukhetha izingxenye: Khetha izingxenye ezinokwethenjelwa okuphezulu nokusebenza okuzinzile, futhi ucabangele izimo zazo zochungechunge lokuhlinzeka. Naka ukusetshenziswa kwamandla kwengxenye kanye nokuphathwa okushisayo.

Isakhiwo se-PCB nomzila:

Isakhiwo: Hlela izingxenye ngendlela enengqondo, ucabangela izindlela zesignali, ukusatshalaliswa kwamandla kanye nezindlela zokukhipha ukushisa. Izingxenye ezibalulekile namasekhethi azwelayo kufanele abekwe phambili.

Izintambo: Ukwahlukanisa ngokwemisebenzi yesekethe ukuze kuqinisekiswe ukusatshalaliswa okunengqondo kwamasignali anesivinini esikhulu, amasiginali e-analog namasignali edijithali. Naka ubude nobubanzi bemikhondo futhi ugweme ama-via amaningi kakhulu.

Ukuphathwa kwamandla: Dala uhlelo lwamandla oluzinzile ukuze uqinisekise ukuthi imojuli ngayinye ithola amandla afanele. Lungiselela ikhwalithi yamandla usebenzisa ama-filter capacitor kanye nenethiwekhi yokusabalalisa amandla (PDN).

Idizayini yokukhipha ukushisa: Ezingxenyeni zokushisisa, klama izixazululo ezifanele zokukhipha ukushisa, njengokwengeza ucwecwe lwethusi lokukhipha ukushisa, usebenzisa osinki bokushisa noma izifeni, njll. Qinisekisa ukusatshalaliswa kokushisa okufanayo kuyo yonke i-PCB.

3. Indlela yokuklama i-PCBA ephelele

Ukulungiselela kokuqala:

Qonda izidingo zephrojekthi ngokuningiliziwe futhi ubhale imininingwane ephelele yedizayini.

Xhumana neminyango efanele (isb. ukuklama kwemishini, ukuthuthukiswa kwesofthiwe, ubunjiniyela bokukhiqiza) ukuze kuqinisekiswe ukwenziwa komklamo kanye nokuhlola.

Dala izinhlelo zokuklama kanye nezikhathi zokuqinisekisa ukuthi amaphrojekthi aqedwa ngesikhathi.

Idizayini yesiyingi nokulingisa:

Sebenzisa isofthiwe ye-EDA yobungcweti yokuklama isifunda ukuze uqinisekise ukuthi umklamo uhambisana nokucaciswa.

Yenza ukuqinisekiswa kokulingisa kumasekhethi abalulekile ukuze uthole futhi uxazulule izinkinga ezingaba khona kusenesikhathi.

Isakhiwo se-PCB nomzila:

Yenza ukwakheka kwe-PCB nomzila kusofthiwe ye-EDA, unake isiginali yobuqotho nobuqotho bamandla.

Sebenzisa inhlanganisela yomzila ozenzakalelayo nokulungiswa mathupha ukuze uthuthukise ukwakheka kwe-PCB.

Ukubuyekezwa kwedizayini nokwenza kahle:

Yenza ukubuyekezwa kwedizayini futhi umeme ochwepheshe abaningi ukuthi babambe iqhaza ukuze bahlole ukunemba nokuba nengqondo komklamo.

Thuthukisa ngokusekelwe kumazwana wokubuyekeza, ukunaka okukhethekile ubuqotho besignali, ubuqotho bamandla, kanye nomklamo oshisayo.

Ukukhiqizwa nokuhlolwa kwe-prototype:

Yenza ama-prototypes, yenza izivivinyo zokusebenza, izivivinyo zokusebenza kanye nokuhlolwa kwemvelo ukuze uqinisekise ukwethembeka nokuzinza komklamo.

Hlaziya futhi uthuthukise izinkinga ezitholakala ngesikhathi sokuhlolwa, futhi uhlele kabusha uma kunesidingo.

Ukulungiselela ukukhiqizwa ngobuningi:

Ngemuva kokuqinisekisa ukuthi ukuhlolwa kwe-prototype kudlulile, lungiselela ukukhiqizwa ngobuningi. Xhumana nabakhiqizi ukuze uqinisekise ukuthi azikho izinkinga ezizovela ngesikhathi sokukhiqiza ngobuningi.

Yakha uhlelo lokuhlola olunemininingwane ukuze uqinisekise ukuthi i-PCBA ngayinye ihlolwa ngokuqinile futhi ihlangabezana nezidingo zekhwalithi.

qhubeka uthuthuka:

Qoqa ulwazi lwempendulo ngemva kokukhiqizwa ngobuningi, hlaziya izinkinga ezivamile, futhi wenze intuthuko eqhubekayo.

Hlola njalo umklamo kanye nezinqubo zokukhiqiza ukuze uthuthukise ukusebenza kahle kokukhiqiza nokulawula ikhwalithi.

Ngokulandela ngokuqinile lezi zinyathelo kanye namaphuzu abalulekile, ungakwazi ukubhekana ngokuphumelelayo nobunzima ekwakhiweni kwe-PCBA, ukuklama i-PCBA yekhwalithi ephezulu, esebenza kahle kakhulu, futhi uhlangabezane nezidingo zamakhasimende kanye nemakethe.